Protect samples from contamination during storage or transport with Thermo Scientific Clean Snap Clear Vials. An innovative snap-off cap reduces the chance of volatile organic contaminants in the environment from passing through the septum while also keeping the septum clean

Volatile Acids DOC316.53.01259 Esterification Method1 Method 10240 50 to 2500 mg/L CH3COOH (Acetic Acid) TNTplus 872 Scope and application: For digested sludges, activated sludges, process water and food products. 1 Adapted from The Analyst, 87, 949 (1962).

12/3/2021 · Overview. We offer access to state-of-the-art mass spectrometry platforms that allow for qualitative, quantitative and structural analysis of lipids,metabolites, pesticides, pharmaceuticals and volatile organic compounds. Our laboratory houses cutting-edge mass spectrometry instrumentation interfaced with liquid chromatography and gas

Low LC/MS Background Samples of Pre-cleaned Mass Spec vials and closures were exposed to acetonitrile at room temperature for 2 hours. Potential non-volatile organic compounds were determined using LC/UV and LC/MS with several ionization techniques

NON-METHANE NON-ETHANE ORGANIC COMPOUND EMISSIONS FROM CLEAN FUELED COMBUSTION SOURCES Section 1 of 5 1. Overview and Applicability 1.1 Principle The procedures used in this Volatile Organic Compound (VOC) source test

Purpose designed for removing solvents from vials and standard ANSI/SLAS-format microplates, the MiniVap® offer quicker dry-down times than traditional methods such as vacuum oven. Typically, the MiniVap® takes less than six minutes to remove volatile organic solvents from your HPLC fractions collected in 24- or 96-well microplates.

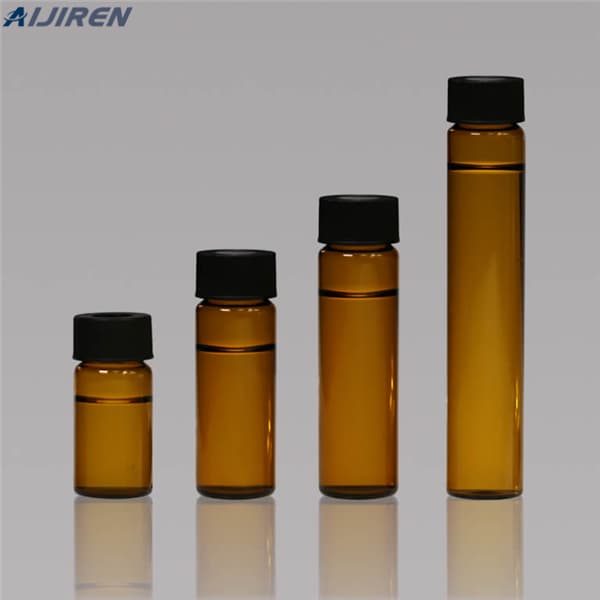

12x32mm Screw Thread Vials, Big Mouth Opening 12x32mm Screw Thread Vials, Standard Opening Crimp Top Vials R.A.M. Large Opening 12x32mm Vials Snap Seal Vials Closures Septa Syringeless Filter Vials Limited Volume Inserts Convenience Packs

The radiocarbon content of dissolved organic carbon (DOC) in rivers, lakes, and other non-saline waters can provide valuable information on carbon cycling dynamics in the environment. DOC is typically prepared for 14 C analysis by accelerator mass spectrometry (AMS) either by ultraviolet (UV) oxidation or by freeze-drying and sealed tube combustion.

Search the world's information, including webpages, images, videos and more. Google has many special features to help you find exactly what you're looking for. Advertising Programs Business Solutions About Google Google.com

Date & Type Update Info 11 April 2011 Updated text Chapter 5: 5.2.1.2 Peristaltic Pump "As a result, this device is restricted from the collection of surface and ground water samples for volatile organic analysis." changed to "As a result, this device is restricted

2. ISO 16000-6: Determination of volatile organic compounds in indoor and test chamber air by active sampling on Tenax TA sorbent, thermal desorption and gas chromatography using MS/FID. 3. ISO 16000-9: Determination of the emission of volatile organic 4.

6.1 SAMPLE CONTAINERS - Clean, amber volatile organic analysis (VGA) vials fitted with PTFE-faced silicone septa and polypropylene screw caps (I-Chem Cat. No. S146-0040 or equivalent). Prior to reuse, wash vials and septa (if not punctured) with detergent and rinse with tap and distilled water.

• Vials were filled with 1.0mL of acetonitrile (LC/MS grade). • The filled vials were capped and the vial+closure incubated at room temperature in the upright position and in the inverted position (in duplicate) for 2 hours. System Suitability Tests • LC/MS –5

Ultra Clean - Ultra Cleaned containers feature a proprietary cleaning process that cleans to 100 or less particles greater than 5 microns. Designed for those needing containers free from particulate contamination our cleaning procedures can utilize a variety of cleaning methods including the use of heated high purity electronics grade filtered water or ultrasonic cleaning depending on customer

Discover how our innovative analytical solutions and services improve all areas of semiconductor, Integrated Circuitry and electronics manufacturing, from process development, process monitoring, QA/QC and failure testing, to assembly and packaging. Research & Development. Device Fabrication. QA/QC & Failure Testing. Assembly & Packaging.